Pali mitundu yambiri ya zida zopangira chakudya, zomwe zida zofunika kwambiri zomwe zimakhudza granulation sizili chabe mphero za nyundo, zosakaniza, ndi makina a pellet.Pampikisano wamasiku ano womwe ukukulirakulira, opanga ambiri amagula zida zapamwamba zopangira, koma chifukwa chogwiritsa ntchito molakwika ndikugwiritsa ntchito, kulephera kwa zida kumachitika nthawi zambiri.Chifukwa chake, kumvetsetsa koyenera kwa njira zopewera kugwiritsa ntchito zida ndi opanga chakudya sikunganyalanyazidwe.

1. Mphero ya nyundo

Chigayo cha hammer nthawi zambiri chimakhala ndi mitundu iwiri: yoyima ndi yopingasa.Zigawo zazikulu za nyundo ndi nyundo ndi zotchinga masamba.Zovala za nyundo ziyenera kukhala zolimba, zosavala, komanso zikhale zolimba pang'ono, zokonzedwa bwino kuti zisamapangitse zida kugwedezeka.

Malangizo ogwiritsira ntchito nyundo:

1) Musanayambe makinawo, yang'anani kudzoza kwa magawo onse olumikizira ndi mayendedwe.Thamangani makina opanda kanthu kwa mphindi 2-3, yambani kudyetsa pambuyo pa ntchito yabwinobwino, siyani kudyetsa mukamaliza ntchito, ndikuyendetsa makina opanda kanthu kwa mphindi 2-3.Zinthu zonse zomwe zili mkati mwa makinawo zitatha, zimitsani injiniyo.

2) Nyundo iyenera kutembenuzidwa nthawi yomweyo ndikugwiritsidwa ntchito ikavala pakatikati.Ngati ngodya zonse zinayi zavala pakati, mbale yatsopano ya nyundo iyenera kusinthidwa.Chidziwitso: Panthawi yosinthidwa, dongosolo lokonzekera loyambirira siliyenera kusinthidwa, ndipo kusiyana kwa kulemera pakati pa gulu lirilonse la zidutswa za nyundo sikuyenera kupitirira 5g, apo ayi zidzakhudza mlingo wa rotor.

3) Dongosolo la ma netiweki a mpweya wa nyundo ndi lofunikira pakuwongolera kuphwanya bwino komanso kuchepetsa fumbi, ndipo liyenera kulumikizidwa ndi chotolera fumbi ndikuchita bwino.Pambuyo pa kusintha kulikonse, yeretsani mkati ndi kunja kwa chotolera fumbi kuti muchotse fumbi, ndipo fufuzani nthawi zonse, yeretsani, ndikuthira mafuta.

4) Zida siziyenera kusakanikirana ndi zitsulo zachitsulo, miyala yophwanyidwa, ndi zinyalala zina.Ngati phokoso lachilendo likumveka panthawi yogwira ntchito, yimitsani makinawo panthawi yake kuti awonedwe ndi kuthetsa mavuto.

5) Kuchuluka kwa ntchito zamakono ndi kudyetsa kwa wodyetsa kumapeto kwa nyundo kumayenera kusinthidwa nthawi iliyonse malinga ndi zipangizo zosiyanasiyana kuti zisawonongeke ndikuwonjezera kuphwanya.

2. Chosakaniza (pogwiritsa ntchito chophatikizira monga chitsanzo)

Chosakaniza chophatikizira chophatikizira chapawiri chimapangidwa ndi casing, rotor, chivundikiro, mawonekedwe otulutsa, chipangizo chotumizira, ndi zina zambiri. Pali ma rotor awiri pamakina omwe ali ndi mbali zozungulira.Rotor imapangidwa ndi shaft yayikulu, shaft ya tsamba, ndi tsamba.Mtsinje wa tsamba umadutsana ndi mtanda waukulu wa shaft, ndipo tsambalo limakokeredwa ku shaft ya tsamba pa ngodya yapadera.Kumbali imodzi, tsamba lomwe lili ndi zinthu zanyama limazungulira pakhoma lamkati la makinawo ndikusunthira kumapeto kwina, kupangitsa kuti nyamayo ikhale yozungulira ndikumeta ubweya wina ndi mzake, kukwaniritsa kusakanikirana kofulumira komanso kofanana.

Malangizo ogwiritsira ntchito mixer:

1) Pambuyo pozungulira tsinde lalikulu, zinthuzo ziyenera kuwonjezeredwa.Zowonjezera ziyenera kuwonjezeredwa pambuyo poti theka lazinthu zazikulu zalowa mumtanda, ndipo mafuta ayenera kupoperamo zinthu zonse zowuma zitalowa mu makina.Pambuyo kupopera mbewu mankhwalawa ndi kusakaniza kwa kanthawi, zinthuzo zikhoza kutulutsidwa;

2) Makinawo akayimitsidwa ndipo osagwiritsidwa ntchito, palibe mafuta omwe amayenera kusungidwa mupaipi yowonjezera kuti asatseke mapaipi atatha kulimba;

3) Posakaniza zipangizo, zonyansa zachitsulo siziyenera kusakanikirana, chifukwa zikhoza kuwononga masamba a rotor;

4) Ngati kutsekedwa kumachitika pakagwiritsidwa ntchito, zinthu zomwe zili mkati mwa makina ziyenera kutulutsidwa musanayambe galimoto;

5) Ngati pali kutuluka kulikonse kuchokera pakhomo lotulutsa, kukhudzana pakati pa khomo lotulutsa ndi mpando wosindikizira wa makina osindikizira ayenera kufufuzidwa, monga ngati chitseko chotuluka sichikutsekedwa mwamphamvu;Malo osinthira maulendo akuyenera kusinthidwa, nati yosinthira pansi pa chitseko cha zinthu iyenera kusinthidwa, kapena chingwe chosindikizira chiyenera kusinthidwa.

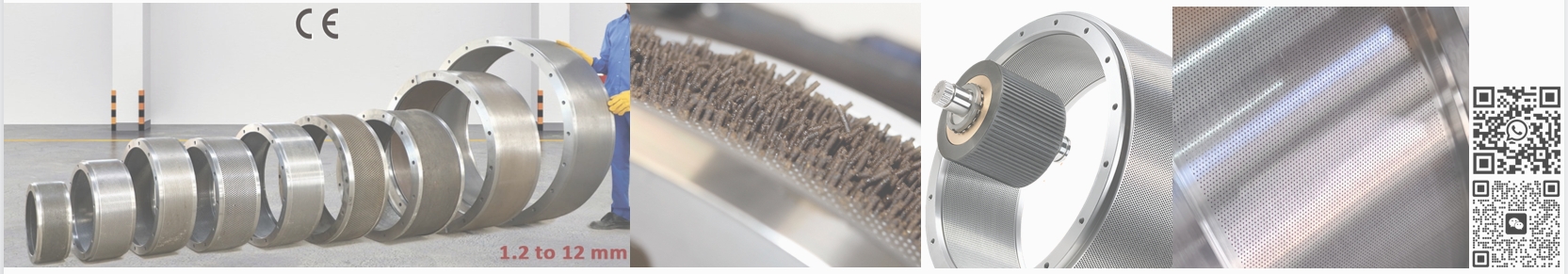

3. Makina opangira mphete

Makina a pellet ndi chida chofunikira kwambiri popanga mafakitale osiyanasiyana odyetsa chakudya, ndipo anganenenso kuti ndiye mtima wa fakitale yazakudya.Kugwiritsa ntchito bwino kwa makina a pellet kumakhudza mwachindunji ubwino wa mankhwala omalizidwa.

Malangizo ogwiritsira ntchito makina a pellet:

1) Panthawi yopangira, zinthu zambiri zikalowa mu makina a pellet, zomwe zimapangitsa kuti ziwonjezeke mwadzidzidzi, njira yotulutsira pamanja iyenera kugwiritsidwa ntchito potulutsa kunja.

2) Mukatsegula chitseko cha makina a pellet, mphamvu iyenera kudulidwa poyamba, ndipo chitseko chikhoza kutsegulidwa kokha makina a pellet atasiya kugwira ntchito.

3) Mukayambitsanso makina a pellet, ndikofunikira kuti muzitha kutembenuza pamanja makina a pellet (kutembenukira kumodzi) musanayambe makina a pellet.

4) Pamene makina sagwira ntchito bwino, magetsi ayenera kudulidwa ndipo makinawo ayenera kutsekedwa kuti athetse mavuto.Ndizoletsedwa kugwiritsa ntchito manja, mapazi, ndodo zamatabwa, kapena zida zachitsulo pothetsa mavuto panthawi yogwira ntchito;Ndikoletsedwa mwamphamvu kuyambitsa mota.

5) Mukamagwiritsa ntchito mphete yatsopano kufa kwanthawi yoyamba, chowongolera chatsopano chiyenera kugwiritsidwa ntchito.Mafuta akhoza kusakaniza ndi mchenga wabwino (zonse zikudutsa mu sieve ya 40-20 mesh, ndi chiŵerengero cha zinthu: mafuta: mchenga wa 6: 2: 1 kapena 6: 1: 1) kutsuka mphete kufa kwa 10 mpaka 20. mphindi, ndipo zitha kuyikidwa muzopanga zanthawi zonse.

6) Thandizani ogwira ntchito yokonza kuti ayang'ane ndikuwonjezera mafuta pamayendedwe akuluakulu kamodzi pachaka.

7) Thandizani ogwira ntchito yokonza kusintha mafuta odzola pa gearbox ya makina a pellet 1-2 pachaka.

8) Tsukani silinda ya maginito okhazikika kamodzi pakusintha.

9) Kuthamanga kwa nthunzi kulowa mu jekete ya conditioner sikudutsa 1kgf/cm2.

10) Kuthamanga kwa nthunzi kumalowa mu conditioner ndi 2-4kgf / cm2 (nthawi zambiri osachepera 2.5 kgf / cm2 akulimbikitsidwa).

11) Mafuta odzigudubuza kuthamanga 2-3 nthawi pa shift.

12) Tsukani chodyetsa ndi chowongolera 2-4 pa sabata (kamodzi pa tsiku m'chilimwe).

13) Mtunda pakati pa mpeni wodula ndi kufa kwa mphete nthawi zambiri ndi wosachepera 3mm.

14) Pakupanga kwanthawi zonse, ndikoletsedwa kwambiri kudzaza injini yayikulu pomwe mphamvu yake ikupitilira yomwe idavotera.

Information Support Contact Information:Bruce

TEL/Whatsapp/Wechat/Line : +86 18912316448

E-mail:hongyangringdie@outlook.com

Nthawi yotumiza: Nov-15-2023